Our Services

At Bedrock Engineering Solutions, we know every project is different — and so is the path to getting it done right. Whether you're just starting your investigation or already nearing implementation, our services scale to meet your needs and deliver value at every stage. Explore our core services to see how we can support your project from start to finish.

Fractional Engineering

-

Simply, get the technical support and results-driven solutions your business needs without maintaining full-time staff engineers.

-

We discuss your application and goals.

We determine the available options.

Then we provide a roadmap to completion.

-

Projects vary based on each and every client’s needs.

Options for hourly rate, fixed project cost and not-to-exceed rates based on the project scope.

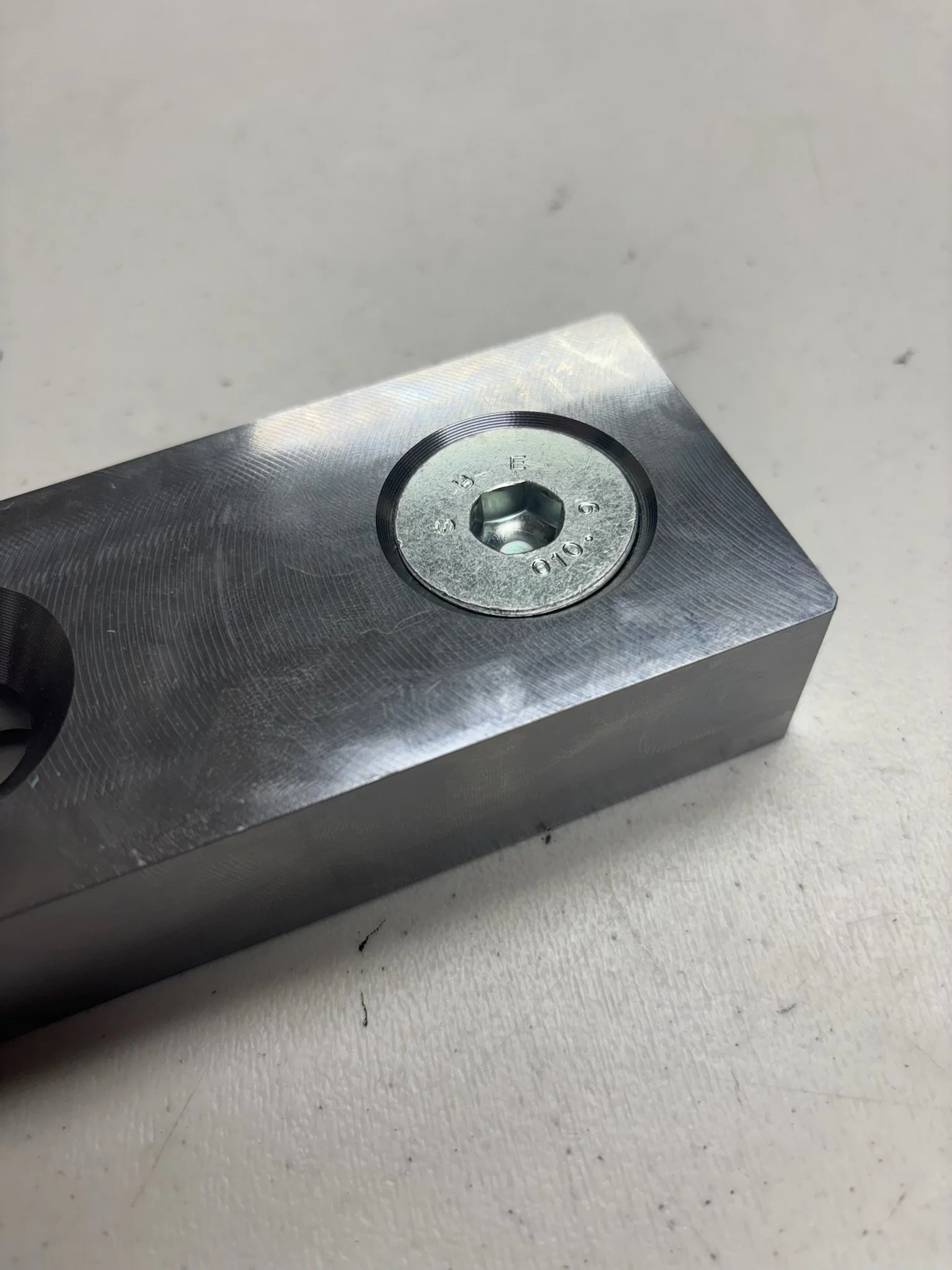

Reverse Engineering & Sourcing

-

If OEM parts become unavailable, we’ll source reliable local replacements to keep your operations running.

-

Innovation is part of any workflow. We can examine a part or process and find ways to improve it for your application.

-

Quality, Price, or Lead time

-Unit price per part

-Service life of a part

-Sourcing lead time

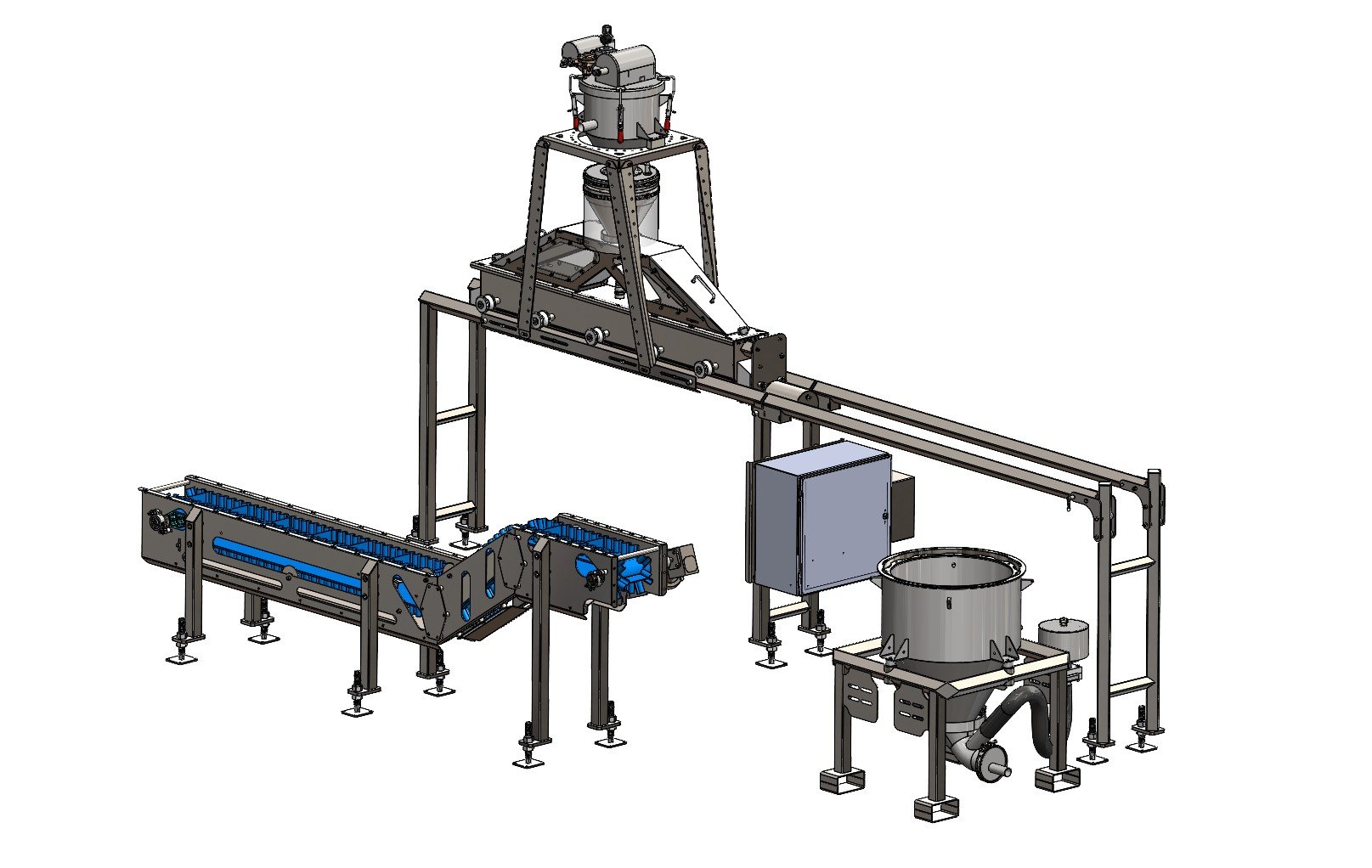

Machine Design & Automation

-

Build-ready designs for fabrication and assembly.

Vendor sourcing and cost reduction

-

Process control tools

Custom automation solutions

3rd party equipment integrations

-

Client experience and insights

Vendor expertise

Technology and innovation

Assembly & Integration

-

Build and assemble our own solutions.

Build to print capabilities.

Onsite assembly and support.

-

Onsite installation

Communication and process integration

Staff training

Diagnostics & Repair

-

Remote and in-person troubleshooting services.

Solution sourcing

-

Sometimes parts are just broken. We can evaluate and help repair components and systems to get you up and running again.

Contact us

Not sure where to start? Reach out. We’ll take a look, ask a few questions, and figure out the next step together.